In 1988, the BFSIOA was established being an interest team of pharmaceutical and affiliated businesses actively involved with BFS processing. The Affiliation was formed to supply its users with an opportunity to exchange Suggestions and views, also to formulate settlement on working specifications.

Wong (Woodstock Sterile Alternatives): One particular significant consideration is comprehending the drug products’s compatibility/interactions with plastic. Prior to picking BFS, there really should be an comprehension of how the product interacts with plastic—if you can find issues about adsorption or absorption, by way of example. Also, plastic containers are permeable in a method that glass is not really, and it can be essential to understand if that should have an effect within the item all over its shelf life.

This automatic technique allows for the productive and aseptic manufacture of these containers, cutting down the potential risk of contamination and ensuring the security and high quality of the ultimate item.

To additional the information and understanding of the procedure controls,Catalent, in collaboration with Air Dispersions Ltd., ran numerous experiments microbially challenging the technique to detect vital Handle parameters and provide the sector with knowledge required to aid this producing process3.

BFS is definitely an aseptic filling technology, but in the situation of injectable solutions there is a regulatory necessity to execute an overkill terminal sterilization (When the product or service can stand up to the method). The most typical route for sterilization is steam autoclaving. The conventional Here's 121 °C.

Comparing operational efficiencies, BFS packaging methods outshine conventional glass filling lines On the subject of Place utilization and output rates.

Shatter resistant shows without any sharp edges lessens the risk of injuries to people and facility staff

You are able to fill beverages or foods health supplements safely and securely and for many years with Blow-Fill-Seal. You furthermore may simultaneously create a beautiful container that aids consumption.

Goll (Weiler): As products applications become more accepted globally, marketplaces necessitating much more stringent regulatory direction are demanding approach enhancements, which decrease risk for an more info added volume of protection on the affected person. The latest progress for Weiler BFS technology may be the introduction of NO2 gasoline sterilization with the grade A filling zone.

As a result of our constant and sustained financial commitment in new higher-pace BFS traces, our large manufacturing capability lets us to tackle new projects of any measurement Anytime.

He explained a tiered cooling notion with several temperature Command models, Each and every which has a consecutively tighter range to increase more info control since they stepped down. 3 units were person circuits around the BFS equipment, just one covering the item tank, one for products piping, and A further for that molds.

Even plastic vials are Employed in automated inspection equipment. Inspection specifications and conditions might be in comparison with vials and syringes for equivalent items. It’s a different strategy for considering,” he claimed.

Temperature considerationsPharmTech: How long may be the merchandise/container at an elevated temperature and so are there any worries relevant to this?

EXAIR's Air Knives present you with a additional effective way to scrub, dry, or interesting components, webs or conveyors on the manufacturing traces. They supply a uniform sheet of laminar airflow with tough-hitting pressure though remaining exceptionally peaceful.

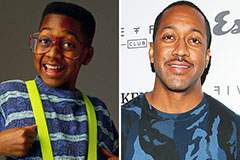

Jaleel White Then & Now!

Jaleel White Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!